With the highest financing record for the first time in the industry, HBD Metal 3D printing helps transform traditional manufacturing in the post-epidemic era.

- Categories : News

- Author:

- Origin:

- Issue Date : 2022-04-29

- Views: 980

With the highest financing record for the first time in the industry, HBD Metal 3D printing helps transform traditional manufacturing in the post-epidemic era.

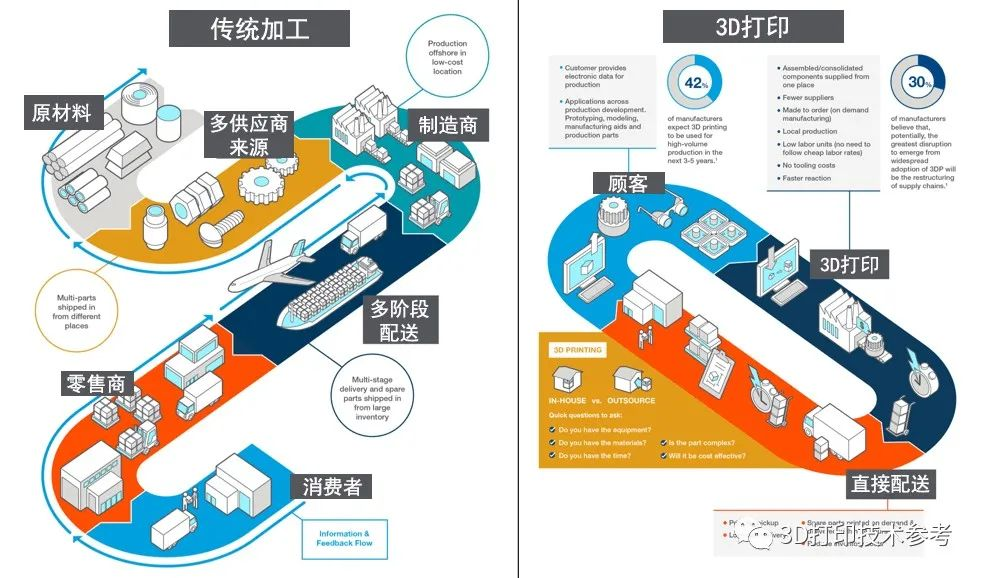

(Summary description)At a time when the COVID-19 crisis is having a huge impact on various industries, 3D printing (Additive Manufacturing) technology is proving to be an exception. Traditional manufacturing companies rely heavily on global supply chains, the production process needs a large number of manufacturing equipment, and 3D printing technology can reduce many process, even settle a matter at one go, which greatly reduces the dependence on different professional personnel and equipment, and relieve the burden of logistics. 3D printing technology is turning "global production" into "local production". According to a study published by the German Federal Association for Information and Communications and New Media industry, nearly 80% of the companies surveyed believe 3D printing technology will have a profound impact on business models and industrial value chains, especially metal 3D printing technology. For countries where the manufacturing industry is almost zero-based, 3D printing has low requirements for technology accumulation and does not need traditional molds. It is the best choice to achieve overtaking on curves and meet the urgent needs of self-use. The epidemic is a test and assessment of 3D printing technology, allowing enterprises to see its huge potential and manufacturing advantages.Against the background, many enterprises have begun to incorporate 3D printing technology into their production processes. At home, there are not only leaders in the aerospace field such as ACAE and CASIC, but also brands in the consumer field such as SAIC, Volkswagen and Gree. Therefore, the well-known 3D printing equipment manufacturers in the industry also get a rare opportunity for development. Take HBD as an example, it has been committed to cooperating with well-known domestic enterprises to jointly use 3D printing in the manufacturing process of traditional products for many years. Through additive thinking and technology implantation, it has truly realized the important value of reducing cost, increasing efficiency and improving quality. Thanks to years of deep cultivation and innovative development ideas, the company won the order of 30 HBD-350T medium-size metal 3D printer in Wenext in December 2021. During the same period, nearly 400 million financing was completed in first round, setting a record for the first time financing in this field.

Next, we will introduce the practical application of HBD in helping traditional manufacturing enterprises to reduce costs and increase efficiency.

- Categories : News

- Author:

- Origin:

- Issue Date : 2022-04-29

- Views: 980

"Expensive", but worth it -- Developing 3D printing molds for well-known household appliance brands.

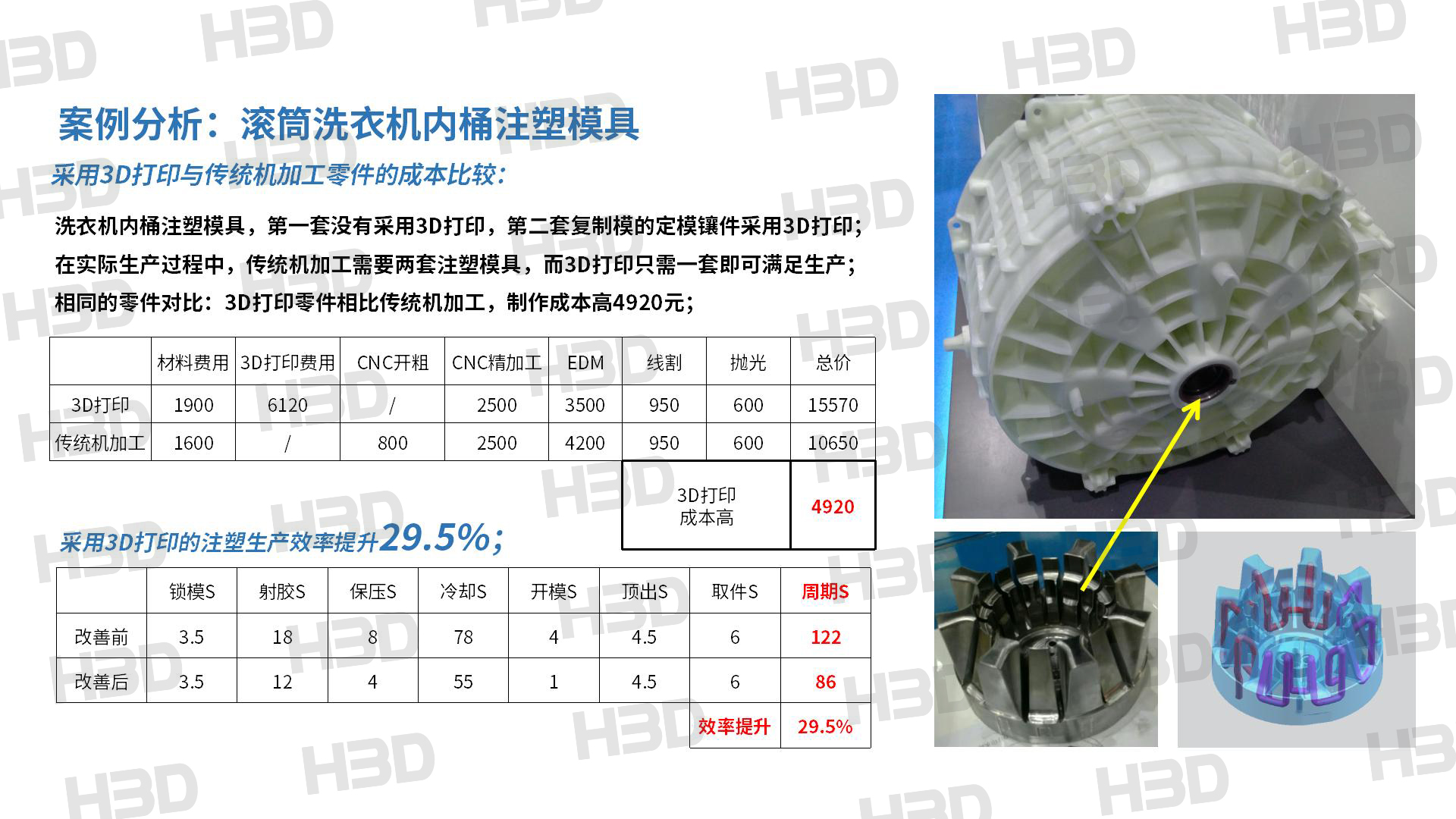

What are the considerations for enterprises to shift from traditional machining to 3D printing manufacturing? The most profound change is that new technologies shorten manufacturing cycles and reduce manufacturing costs. Taking a well-known domestic household appliance brand as an example, the application of 3D printing fixed mold inserts with conformal cooling channel makes it truly realize the value of 3D printing.

In the process of injection molding, the proportion of cooling is about 60% of the molding cycle. It is the focus of the enterprise to shorten the cooling cycle and improve the product quality. Metal 3D printing moulds or mould inserts with conformal cooling function can well solve the pain points that customers are concerned about, reduce the investment of enterprises on injection molding machine equipment, site and personnel, and thus greatly reduce the manufacturing cost and improve the profits of enterprises.

The traditional mold processing is limited by the existing processing technology, and the cooling mode is usually horizontal and vertical pipe, which can not realize the conformal cooling channel inside the mold, which greatly affects the temperature distribution and cooling efficiency of the mold surface, and ultimately affects the product production cycle and product quality. Laser metal 3D printing technology uses powder layer by layer melting technology, which theoretically can achieve any required geometric shape, endowing design freedom, so that designers are no longer limited by traditional processing technology, truly realize the mold’s internal conformal cooling channel design.

Drum washing machine inner cylinder injection mould

The HBD-350 printed mold steel drum washing machine inner cylinder injection mold has a sample size of 195.84*195.84*106.27mm. The forming size of HBD-350 is 325*325*400mm, adopting the upper powder feeding structure, the bidirectional variable speed powder recoating mode and the dual laser configuration, combined with the large layer thickness printing process, to achieve the ultimate pursuit of printing efficiency under the premise of ensuring high-quality printing quality. Through the actual injection molding comparison, it is found that the inner cylinder mold with 3D printed conformal cooling channel is 29.5% more efficient than the traditional machined mold in single-piece production, the daily production volume of the product is increased by 40.7%, the production efficiency is improved obviously.

In terms of the manufacturing cost, the mold cost of 3D printed is higher than that of traditional processing, but in terms of overall output benefits, the comprehensive benefits of using 3D printing conformal cooling channel solutions are much higher than those of traditional methods, as following output data comparison shows:

Through a comprehensive comparison, the 3D printing products can obviously improve the production efficiency and cost optimization for traditional manufacturing enterprises. In this case, the company needs 118,000 injection molding products every year, and the adoption of new technologies can save the company about CNY 200,000, which is why domestic high-end manufacturing companies have begun to incorporate 3D printing into their production systems. At the same time, it is also profitable for 3D printing companies. The annual sales of washing machines are as many as hundreds of thousands or even millions of units, the demand for molds can be imagined, 3D printing companies can go deeper into traditional manufacturing than before.

Integrated design and extreme feature manufacturing - Improve product efficiency and comprehensive benefits.

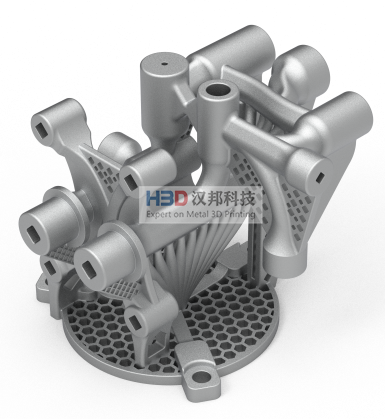

Another transformation brought by 3D printing is the integrated part design and manufacturing. The currently well-known one is GE's integrated fuel nozzle, which turns 20 parts into a whole, and the 855 parts of the Catalyst turboprop have been structurally optimized and reduced to 12 parts. Integrating multiple components into a single component for manufacturing can not only reduce the number of parts, but also reduce assembly, welding and other processes, thereby reducing the dependence on personnel and the risks or hidden dangers in each process. Integrated molding has been demonstrated to have a significant impact on nearly 60 items, involving the entire product manufacturing chain.

In the customer case of HBD, it has carried out integrated design and manufacture for a hydrogen energy system component. The part is traditionally composed of more than 20 parts, with a complex structure, and is separately manufactured by casting process, which takes a long time to manufacture and complex processes. Using 3D printing integrated design and printing, the entire manufacturing cycle is only 37 hours, which not only greatly reduces product delivery time, but also increases product safety.

Hydrogen energy complex structural component manufactured by HBD

Hydrogen energy complex structural component manufactured by HBD

At the same time, compared with traditional product manufacturing, the integrated molding technology also involves the simplification of the product manufacturing process, such as reducing the processing links in the previous QA and QC processes, eliminating the traditional inventory, and optimizing the product supply chain. It is a proven way in which new technology changes traditional manufacturing.

3D printing also changes traditional manufacturing in the manufacture of extreme structural features, such as by redesigning the hydraulic manifold to reduce 90° angle to improve fluid loss, eliminate plugs and reduce leak points. The overall part weight was reduced by 81% thanks to structural optimization.

Hydraulic manifold manufactured by HBD(designed by Gen3D)

Shoe mold is another application by using 3D printing the extreme structural features. The metal 3D printing technology represented by the laser powder bed fusion (LPBF) process can achieve a manufacturing limit of 0.03mm, which is very useful for shoe mold manufacturing. The traditional shoe mold processing process is very complicated and relies heavily on manual skills. The main method of sole texture treatment is etching treatment, which requires a large amount of chemical products for surface treatment (pickling), which causes much damage to the health of operators and the environment. On the other hand, 3D printing can realize the bottom texture manufacturing at one time, and no need for casting and post-biting treatment, which greatly improves the efficiency, saves personnel costs, and greatly shortens the product delivery cycle.

Shoe mold printed by HBD metal 3D printer

In the industrial field, applications such as non-standard parts, precision castings, and molds have been rapidly promoted. The use of 3D printing technology can shorten the production cycle and improve production efficiency. In the post-epidemic era, the manufacturing industry will pay more attention to the stability and reliability of the supply chain, people will pay more attention to 3D printing technology, the understanding of the technology will be deeper than before, and the acceptance and use of the technology will also be higher.

HBD has been deeply involved in the industry for many years, and has highly technical sensitivity and practical spirit. In the future, it will form a back-to-back mutual trust cooperation with upstream and downstream partners with the spirit of "Metal 3D Printing Craftsman" to promote the in-depth application of metal 3D printing in traditional manufacturing and the development of new industry solutions.

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback