HBD donated one million yuan to Guangdong University of Technology to help the research and development of core common technologies for laser additive materials

- Categories : News

- Author:

- Origin:

- Issue Date : 2022-04-11

- Views: 603

HBD donated one million yuan to Guangdong University of Technology to help the research and development of core common technologies for laser additive materials

(Summary description)On April 08, 2022, Guangdong Hanbang 3D Tech Co., Ltd. (“HBD”) donated one million yuan to Guangdong University of Technology Education Development Foundation to further strengthen cooperation and build "Guangdong University of Technology-Guangdong Hanbang 3D Tech Co., Ltd. Metal Additive Manufacturing Technology Joint R&D Center” ( “GDUT-HBD Metal Additive Manufacturing Technology Joint R&D Center” ).

- Categories : News

- Author:

- Origin:

- Issue Date : 2022-04-11

- Views: 603

Guangdong Hanbang 3D Tech Co., Ltd. and Guangdong University of Technology Education Development Foundation jointly held an "online + on-site" donation ceremony. Mr. Liu Jianye, the Chariman of HBD, the Deputy General Manager Qi Wenjun, the Deputy General Manager Chen Jilin, Manager Lin Lin, Manager Li Yanqing and other company representatives, Deputy President Wang Chengyong of Guangdong University of Technology, Director Lu Renquan of the Scientific Research Management Department, Director He Zhenyan of the Office of External Liaison and Alumni Affairs, Secretary Tang Jianwei and Deputy Dean Zheng Lijuan of the School of Mechanical and Electrical Engineering, and Deputy Director of the GDUT-HBD Metal Additive Manufacturing Technology Joint R&D Center Associate Professor Yang Yang, Associate Professor Li Sheng and some postdoctoral and postgraduate representatives attended the donation ceremony.

The donation ceremony was presided over by Deputy Dean Zheng Lijuan of the School of Mechanical and Electrical Engineering, Guangdong University of Technology. Firstly, she introduced the leading guests who attended the donation ceremony, and played the introduction video of HBD and the introduction video of the cooperation process between Guangdong University of Technology and HBD. Both schools and enterprises signed the donation agreement on behalf Deputy Manager Chen Jilin of HBD, Director He Zhenyan Representative of the Education Development Foundation, and Secretary Tang Jianwei of the School of Mechanical and Electrical Engineering. Subsequently, Deputy General Manager Chen Jilin of HBD, had donated the check to Director He Zhenyan Representative of the Education Foundation. At the same time, Director He Zhenyan issued a donation certificate and souvenirs to Deputy General Manager Chen Jilin.

In his speech, Chariman Liu Jianye of HBD expressed his affirmation of the long-term school-enterprise cooperation model between HBD and Guangdong University of Technology and the road of collaborative development of production, education and research. And said that through this donation, the two parties will continue to deepen cooperation in platform construction, key projects, standard setting, scientific and technological honors and personnel training to achieve common development, strive to cultivate more high-end talents, and enhance the high-level research and enchance the strength of HBD R&D team. By undertaking high-level R&D projects, forming a core technological innovation force that continues to support the development of the industry, these efforts will help HBD become a global leader in the new generation of metal 3D printing, and will be used in metal 3D printing high-end molds, aerospace, medical, in the field of intelligent manufacturing, and make greater contributions to the national intelligent equipment manufacturing industry and social and economic development.

Lu Renquan, the Director of Scientific Research Management Department of Guangdong University of Technology, expressed his heartfelt thanks to Hanbang Technology for its strong donation and support to the school's scientific research undertakings, and introduced the research team of efficient precision manufacturing technology and equipment of Guangdong University of Technology ( “IMT” ). He also expressed his hope for future development in scientific research, industry-university-research cooperation, talent training and scientific and technological honors, and looked forward to in-depth cooperation with Hanbang Technology in more fields to achieve fruitful results.

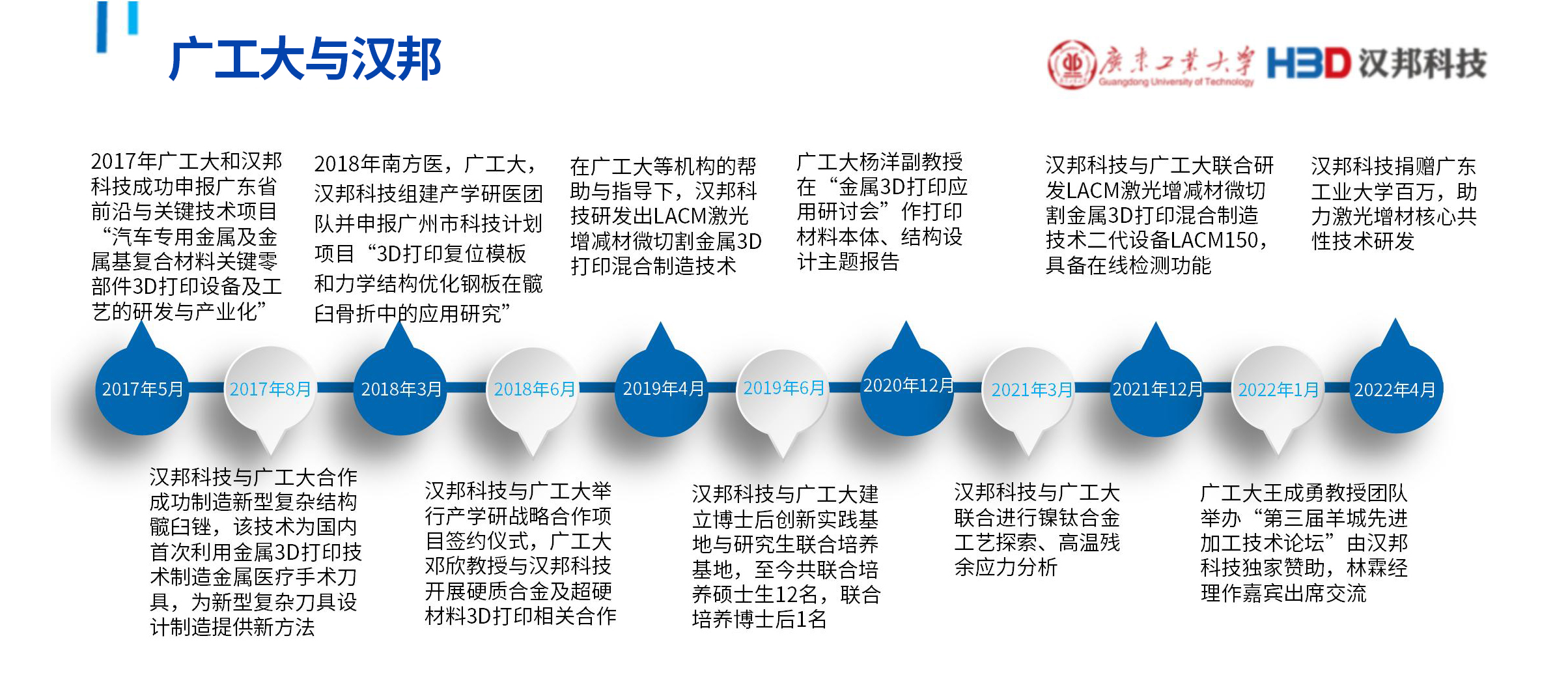

Deputy President Wang Chengyong delivered a speech on behalf of Guangdong University of Technology, GDUT-HBD Metal Additive Manufacturing Technology Joint R&D Center and IMT team. He first thanked HBD for its donation, and reviewed the progress of a number of industry-university-research cooperation between Guangdong University of Technology and HBD since the joint establishment of the " GDUT-Hanbang Technology Metal Additive Manufacturing Technology Joint R&D Center" in 2017. At the same time, he hope that in the future, will continue to increase the depth of long-term cooperation and research in the field of additive manufacturing with HBD, and make good use of donations to achieve long-term development goals for HBD, and make new achievements for school scientific research, discipline construction and personnel training.

Guangdong University of Technology and HBD have carried out long-term strategic industry-university-research cooperation, and jointly established the "GDUT-Hanbang Metal Additive Manufacturing Technology Joint R&D Center", "Post-doctoral Innovation Practice Base", "Guangdong Province Postgraduate Joint Training Base ( Zhongshan)". Guangdong Province Postgraduate Joint Training Base (Zhongshan) Hanbang Technology Joint Training Demonstration Site has recruited 20 graduate students majoring in mechanical engineering jointly with Guangdong University of Technology. It has achieved rich cooperation results in many projects such as LACM equipment, multi-laser additive and subtractive manufacturing equipment, additive manufacturing online monitoring technology, and medical device additive manufacturing technology, and jointly applied for more than 10 patents.

After the meeting, the two parties conducted in-depth discussions on the strategic direction and content of the follow-up project research and development, and conducted exchanges and discussions on the current key cooperation projects such as "multi-laser material addition and subtraction equipment and technology research and development". Both parties expressed their expectation to open a new chapter of cooperation in the field of new precision manufacturing technology and equipment research and development.

About HBD

HBD, a leading manufacturer of industrial-grade metal (SLM) 3D printing equipment in China, is located in Zhongshan City, Guangdong Province. The HBD founding team stepped into the metal 3D printing industry in 2007, and commericialize the metal 3D printing (SLM) equipment with R&D, production, sale, and application technology. In 2021, HBD had completed the first round of financing of nearly RMB 400 million. By the end of 2021, the cumulative output of HBD will exceed 500 units, with sales and installations in nearly 40 countries around the world, including Southeast Asia, Europe, North America, South America, the Middle East, etc., leading the industry in installed capacity.

HBD has a large amount of application technology and data accumulation through continuous innovation and iteration of metal 3D printing equipment, software, control system, process and technical parameter library; with solid industry deep cultivation and technical research, it has obtained more than 180 technical patents and software copyrights, and participated in the formulation of national standards for additive manufacturing, 11 industry standards and 2 group standards as the main drafter, and gathered a strong resource of cooperative experts. HBD has covered applications in Aerospace, Medical-Dental, Orthopedics, New Energy, Mold & Die, Automobile, Personalized Customization, Education & Scientific Research, etc., Cumulatively serving thousands of customers and has been highly recognized by customers and reached long-term strategic cooperation, including China Iron and Steel Research Institute (CISRI), Gree, Sunshine-laser, Shanghai Jiao Tong University and other famous enterprises and universities.

HBD is committed to becoming a master craftsman in the metal 3D printing industry. Relying on strong advanced equipment design and manufacturing capabilities, it has developed a total of 23 models in large, medium and small sizes. It has successfully developed multi-light path metal 3D printing large-size equipment of HBD-400, HBD-1000 and HBD-1500 models. At present, it has reached stable cooperation with many top scientific research institutes and aerospace companies and supplied them in batches. From metal additive manufacturing technology to the international leading technology LACM laser adding and subtracting material composite processing technology. Based on intelligence, automation and digitalization, HBD provides integrated high-quality metal 3D printing solutions, provides customers with more efficient and flexible new business cooperation methods, and continues to create maximum value for customers.

About IMT

The IMT team is committed to comprehensively improving the research and technological innovation capabilities of the application basic theory, application basic technology, tools and equipment of efficient, precise and green manufacturing technology. The IMT team builds a basic scientific theoretical system for precision manufacturing of high-performance parts/components in mechanical manufacturing science. It is one of the earliest major research teams in China engaged in high-speed machining, hard and brittle material processing, printed circuit board processing, biological tissue removal and medical equipment and coating tools. Their main research areas are high-efficiency and precise green manufacturing technology and equipment for difficult-to-machine materials, as well as minimally invasive surgical instrument design and precision manufacturing, etc.; involving machining, metal and non-metal additive manufacturing, ultrasonic processing, laser processing, FIB processing, CT and Image recognition and detection, surgical assistance robots and other fields. The IMT team has Guangdong Provincial Key Laboratory of Minimally Invasive Surgical Instrument Design and Precision Manufacturing, Guangdong University Modern Product Design and Manufacturing Technology Laboratory, Guangdong Province Printed Electronic Circuit Manufacturing Engineering Technology Research Center, and Guangdong Province High-tech Ceramic Precision Manufacturing Engineering Technology Research Center, etc.. It has carried out close industry-university-research cooperation with several key enterprises at home and abroad, established a number of cooperative research and development institutions, and achieved industrialization of many research and development results, and achieved good social and economic benefits. The research and development achievements of the IMT team have won the second prize of National Science and Technology Progress Award (2019), the first prize of China Machinery Industry Science and Technology Award (2018), the first prize of Guangdong Science and Technology Progress Award (2020, 2014), The second prize of Guangdong Province Natural Science Award (2009) and the second prize of Guangdong Province Science and Technology Progress Award (2006).

The IMT team will strive to become an important research base for solving the core scientific problems and key common technical problems of the country, especially the modern industry, strategic emerging industry and medical device health industry in the Guangdong-Hong Kong-Macao Greater Bay Area. Provide basic, strategic and forward-looking advanced manufacturing technology for the long-term development of high-end equipment, communication technology, microelectronics 3C, new energy vehicles, aerospace, high-performance medical equipment, marine engineering, rail transit and other industries in the provincial manufacturing industry Knowledge reserve, technology and talent support.

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback