Explore Tungsten Powder for Additive Manufacturing

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2023-12-15

- Views: 833

Explore Tungsten Powder for Additive Manufacturing

(Summary description)Tungsten, known as Wolfram in many parts of the world, boasts a list of impressive attributes. Its high melting point, outstanding thermal conductivity, and remarkable density set it apart from most other materials. These inherent properties make tungsten a top choice for a wide range of applications.

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2023-12-15

- Views: 833

In the world of advanced materials, one element stands out for its exceptional properties and versatility: tungsten. With a history dating back to the early 17th century, tungsten has played an indispensable role in various industries, thanks to its unique combination of characteristics. Today, we explore the diverse applications of this remarkable element and how it continues to transform industries worldwide.

The Strength of Tungsten:

Tungsten, known as Wolfram in many parts of the world, boasts a list of impressive attributes. Its high melting point, outstanding thermal conductivity, and remarkable density set it apart from most other materials. These inherent properties make tungsten a top choice for a wide range of applications.

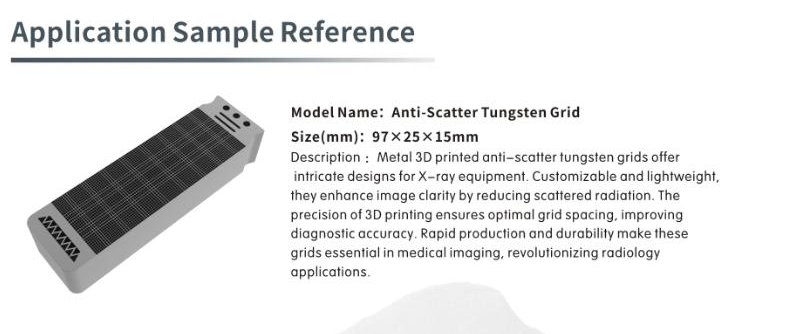

Medical Devices: Tungsten is often used in medical equipment due to its biocompatibility and radiation shielding properties. LBPF can be used to create intricate and customized medical implants, radiation shields, and other medical devices.

Electronics and Semiconductors: Tungsten's high melting point and excellent electrical conductivity make it suitable for various electronics and semiconductor applications. LBPF can help create complex heat sinks, electrodes, connectors, and other components used in electronic devices.

Tooling and Cutting Applications: Tungsten is known for its hardness and wear resistance, making it ideal for tooling and cutting applications. LBPF can enable the production of intricate cutting tools, molds, and dies with complex geometries.

Energy Industry: Tungsten is used in various energy-related applications, including components for solar panels, turbine blades, and electrical contacts. LBPF can help manufacture components that require high temperature and corrosion resistance.

Aerospace: Tungsten parts manufactured using LBPF can find applications in aerospace to their high density, thermal resistance, and ability to withstand extreme conditions. Components such as engine parts, nozzles, heat shields, and structural elements can benefit from the properties of tungsten.

The Future of Tungsten:

Tungsten's inherent properties, combined with the sustainable practices of modern manufacturing, contribute to a more eco-friendly future. Its use in additive manufacturing techniques, such as Laser Powder Bed Fusion (LBPF), reduces material waste, making it a responsible choice for industries seeking sustainability.

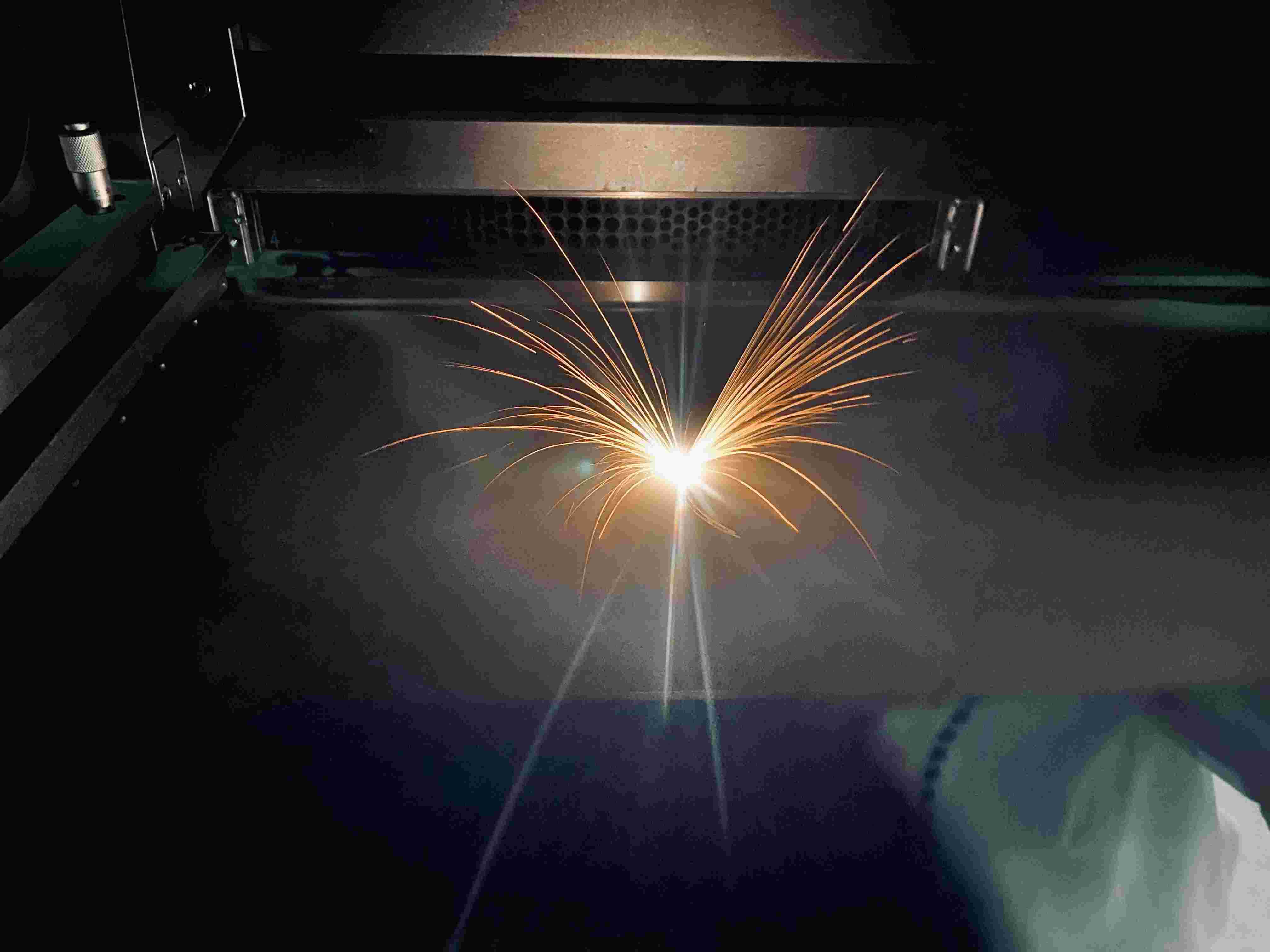

HBD Laser Powder Bed Fusion Technology

As technology evolves, so do the applications of tungsten. With advancements in materials science and manufacturing techniques, the possibilities are boundless. Customization, precision, and the ability to fine-tune tungsten's properties for specific needs are at the forefront of innovation.

At HBD, we are proud to be a part of this exciting journey. Our expertise in 3D metal additive manufacturing, particularly with tungsten materials, allows us to unlock new dimensions of creativity and performance for our clients across industries.

To explore how HBD is harnessing the potential of tungsten and other advanced materials through 3D metal additive manufacturing, please contact our team of experts below.

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback