HBD Case Study: Additive Manufacturing Application of Cooling System for TJU Racing Team

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2023-08-26

- Views: 416

HBD Case Study: Additive Manufacturing Application of Cooling System for TJU Racing Team

(Summary description)HBD-printed exhaust system components met performance expectations, ensuring ease of installation even with minimal permissible deviations due to high printing precision. Material performance was validated during subsequent testing, demonstrating resistance to high temperatures and pressures, while maintaining smooth internal surfaces. This has significantly contributed to the exhaust system's durability and power enhancement.

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2023-08-26

- Views: 416

Background of TJU Racing Team

Established in 2007, the TJU Racing Team is affiliated with Tongji University's College of Automotive Engineering. Comprising over 120 members, the team operates across five departments: Chassis, Powertrain, Electronics, Body and Aerodynamics, and Business Management. Diverse talents from the College of Automotive Engineering, Mechanical Engineering, Telecommunications, Business Administration, Arts, and Media Studies contribute to the team's success.

TJU Racing Team operates as a semi-commercial racing team, supported by the university, college, and sponsors. With annual design and manufacture of racing cars, they actively participate in domestic and international FSAE competitions. Their independent management and operation model reflect their commitment to student-driven initiatives. The team's prowess has garnered widespread attention, featured by media outlets including CCTV and Automotive Enthusiast. They have been invited to prestigious events such as the Shanghai International Auto Show, World Internal Combustion Engine Congress, and China International Import and Export Fair.

With over a decade of experience, TJU Racing Team has designed and manufactured more than ten racing cars. In the past 11 years, they've consistently participated in competitions in Japan, achieving notable accolades and even setting new records. Their accomplishments include achieving fourth place overall (hybrid category), third place in the combustion category, first place in aerodynamics design, second place in CAE design, third place in suspension design, and several other awards at the 2019 Japan FSAE competition. Their dedication has propelled them to outperform traditional international powerhouses.

Application of Cooling System

The focus of this case study is the implementation of a cooling system in the design of TJU Racing Team's formula-style racing cars.

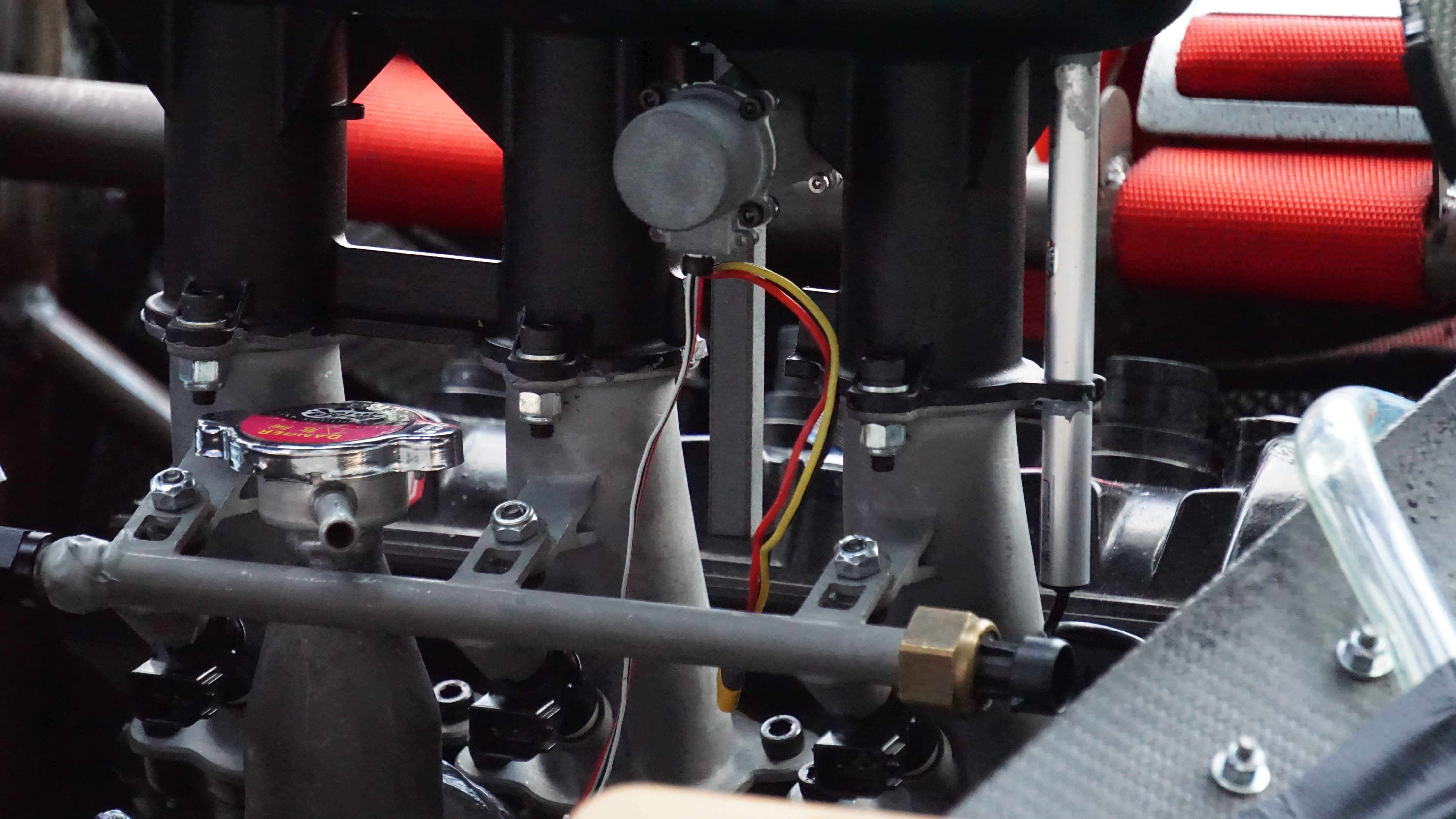

Cooling Systems in TJU formula-style racing car

Challenges and Opportunities

Designing formula-style racing cars involves balancing flexibility with adherence to competition rules. The challenge lies in reconciling theoretical design with practical manufacturing to optimize the car's performance. Ensuring the car meets lightweight requirements is crucial. However, using titanium alloy for the exhaust system, a preferred material for high-performance cars, presents difficulties due to irregular geometries at junctions and manifold areas. Traditional manufacturing methods would result in high costs, poor precision, and limitations in design geometry, jeopardizing the balance between lightweight and high-performance goals.

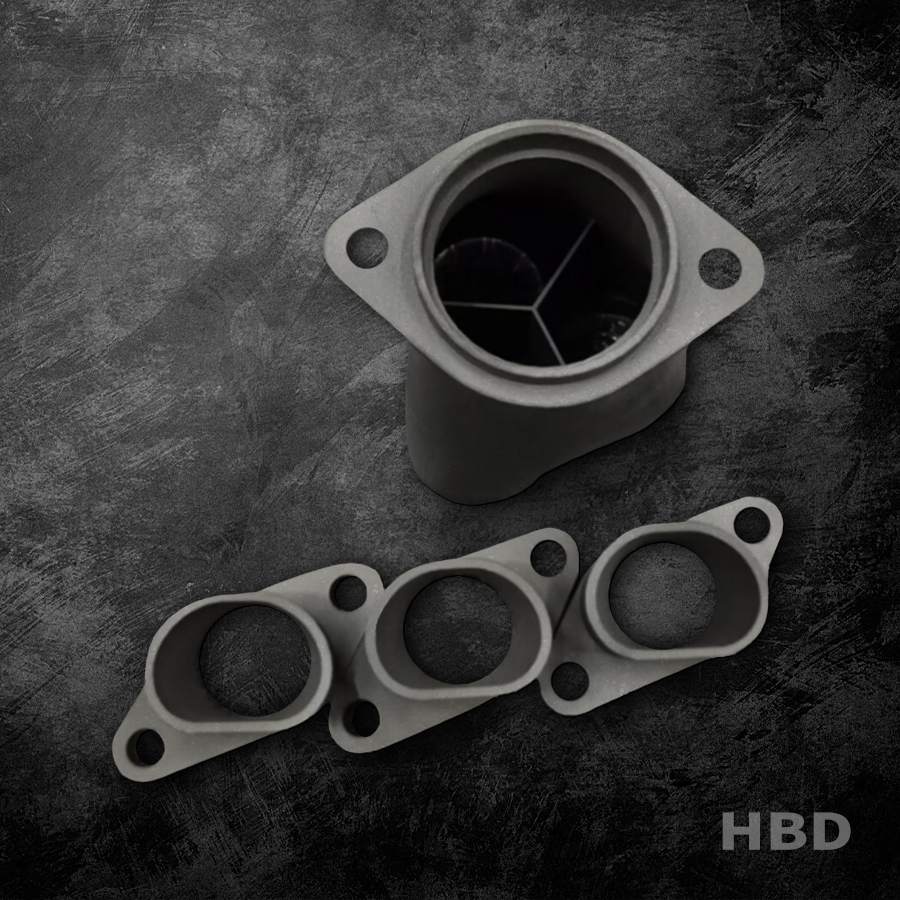

The exhaust manifold's complexity, featuring irregular tapered surfaces with three openings on one side for exhaust manifolds and a flange on the other side for easy connection, along with internal partitions to ensure even exhaust flow, makes traditional manufacturing nearly impossible.

The exhaust manifold

The exhaust header adapter connects the engine exhaust port to the exhaust manifold, transforming the irregular geometry into a regular circular shape for further processing. It also has two holes on each side for bolting to the exhaust manifold.

Exhaust header adapter connects engine exhaust port to exhaust manifold

Reasons for Choosing HBD

The team designed two cooling components to connect the engine and the cooling pipeline. Direct contact with the engine casing and the use of worm gear clamps for the cooling pipeline necessitated heat resistance and stiffness. Aluminum alloy was chosen as the material due to its lightweight properties. Given the complex and irregular surfaces of the designed parts, metal 3D printing was selected as the production method.

Having previously collaborated with HBD, the team's positive experience with their products in the 2021 season affirmed their decision. The durability and performance of HBD-produced components met the team's race and testing needs over nearly two years, reinforcing their choice. HBD, a leading Chinese manufacturer of industrial-grade metal additive manufacturing equipment, has a history of innovation and collaboration across industries such as aerospace and automotive.

TJU formula-style racing car made from HBD 3D printed parts

HBD Printed Products

Depicts the connecting part between the engine inlet and the cooling pipeline, known as the "inlet manifold." With a dual radiator cooling system, cooling water exits both radiators, converges at the inlet manifold, enters the engine through the inlet, and aids in engine cooling.

Depicts the connecting part between the engine outlet and the cooling pipeline, known as the "outlet manifold." Cooled water exits the engine via the outlet manifold, divides into two streams, passes through the cooling pipeline, and enters the dual radiators to further reduce temperature. Additionally, the part is integrated with a degassing container, aiding in bubble removal during the water-filling process.

Combining the inlet and outlet manifolds with other cooling components achieves effective water circulation.

Customer Feedback and Evaluation

HBD-printed exhaust system components met performance expectations, ensuring ease of installation even with minimal permissible deviations due to high printing precision. Material performance was validated during subsequent testing, demonstrating resistance to high temperatures and pressures, while maintaining smooth internal surfaces. This has significantly contributed to the exhaust system's durability and power enhancement.

The use of HBD products resolved exhaust system manufacturing challenges and facilitated exploration of innovative geometric designs. Additionally, the adoption of lightweight titanium alloy significantly reduced weight compared to traditional methods, resulting in improved exhaust flow and reduced backpressure. In conclusion, HBD-printed exhaust system components have notably elevated the car's performance.

TJU's team of experts with TJU formula-style racing car

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback