Quick!New! Big! The Era of Mass Manufacturing!

- Categories: Events

- Author:

- Origin:

- Time of issue: 2023-03-11

- Views: 0

Quick!New! Big! The Era of Mass Manufacturing!

(Summary description)On March 9, 2023 International Advanced Manufacturing (Guangdong, China) Summit with the theme of "High-Quality Reshaping Pattern, Innovation and Recycling" was successfully held in Dongguan Songshan Lake. The summit was supported and guided by China Mould Industry Association and Guangdong Productivity Promotion Center, sponsored by Guangdong Machinery Mould Technology Promotion Association, and co-organized by Shanghai Hanbang United 3D Tech Co., LTD. Under the guidance of the high-quality development strategy of the state and Guangdong Province, the summit analyzed the internal survival logic, development coordinates and force dimensions of the mold and related manufacturing industry, and explored the road of high-quality development of reshaping the pattern, improving the cycle, committed to innovation and collaborative endeavour. Hanbang Technology and many business associations, industry giants, top 100 enterprises, experts and scholars jointly attended and made wonderful keynote speeches.

Theme Sharing of Mold Industry Value Chain

▲HBD Technology Development and Product Application Director Niu Liuhui Speech

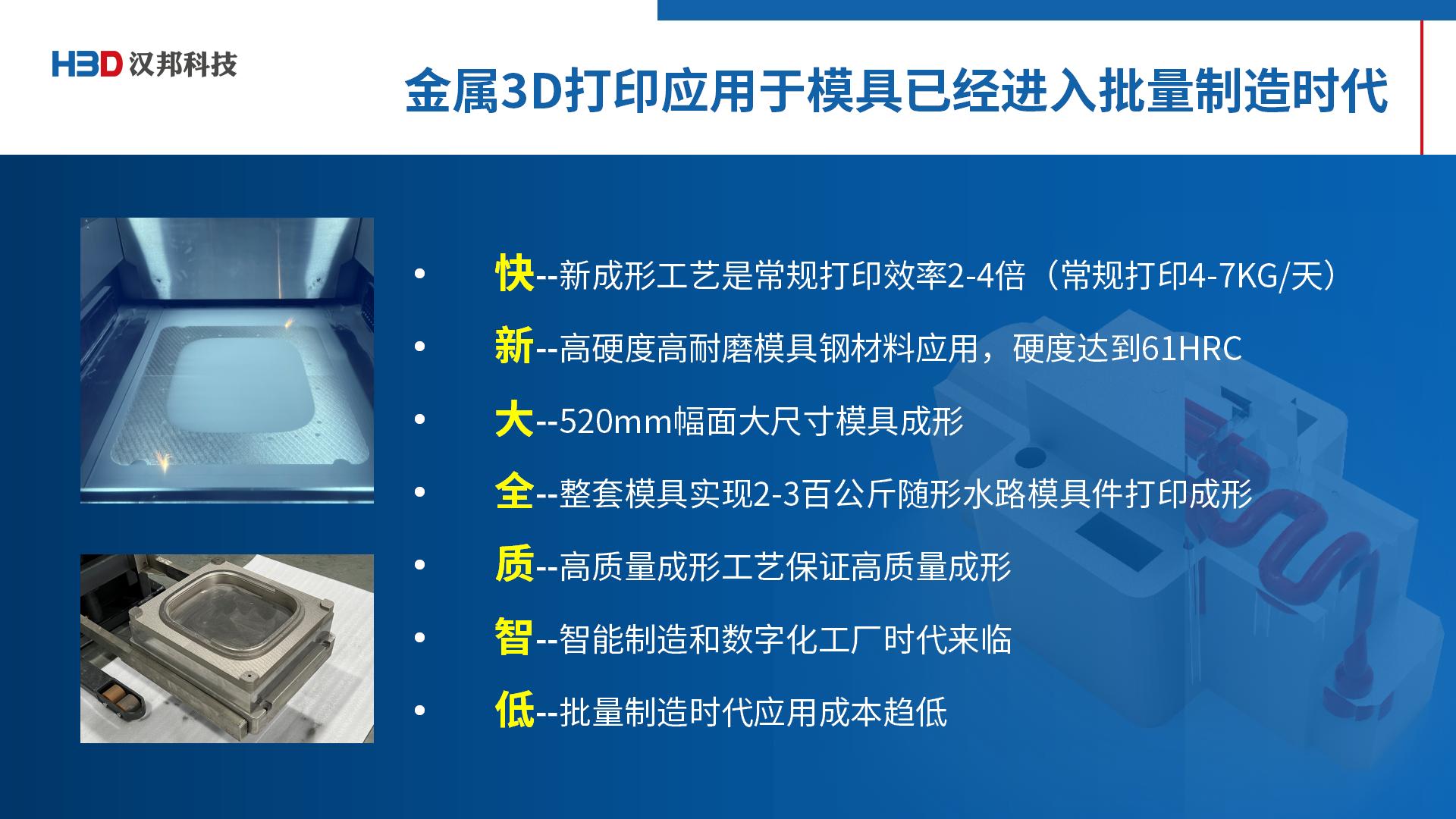

Niu Liuhui, director of process development and product application of HBD, made a keynote speech on "Innovation and application trend sharing of metal Additive Manufacturing mold industry value chain". Director Niu said that the mold has entered the era of mass production in the application of metal additive manufacturing, and the improvement of application technology has brought about the reduction of 3D printing costs. The printing and forming of 200-300 kg of random waterway mold parts has been generally realized.

Award Ceremony

▲Award Ceremony

After the summit, the 11th member Congress of Guangdong Machinery and Mould Science and Technology Promotion Association exchange dinner and high quality enterprise award ceremony were held. Guangdong Machinery and Mould Technology Promotion Association would like to thank HBD for its support and dedication to the 8th International Advanced Manufacturing (Guangdong, China) Summit, and award a plaque.

Guangdong Machinery and Mould Science and Technology Promotion Association awarded Mr. Niu Liuhui the honorary title of "2023 AMIS International Advanced Manufacturing (Guangdong, China) Summit Speech Contribution".

▲HBD Chairman Liu Jianye Made a Speech

Liu Jianye, chairman of HBD, delivered a speech as a representative of high-quality enterprises. Liu said that he was very grateful to the Guangdong Model Association for this platform, which brings us very pragmatic services, leads you to learn the industry benchmarking, visits and learns the business management model of the example, and conducts business docking. HBD has long focused on metal 3D printing equipment, while providing related self-developed software and high-strength materials, such as AMES additive manufacturing intelligent system for full printing process management, high wear resistance mold steel above 60 degrees HRC60, large-scale additive workshop and process planning scheme. We are more willing to come to the customer site, fully open technical exchanges, with good equipment and good service to implemente the customer's cost and profit.

Visit Shenzhen WeNext Technology Co., Ltd.

On the morning of March 10th, Guangdong Machinery Mold Technology Promotion Association, Qingdao Mold Industry Association and many well-known outstanding entrepreneurs came to HBD strategic partner - Shenzhen WeNext Technology Co., Ltd. Zhang Shuhao, General manager of the Additive Business Division, and Li Shuoyang, senior director of the metal Additive Manufacturing Business Division introduced the current situation of the company's innovation and development.

WeNext Technology Co., Ltd (WeNext), the first and largest 3D printing service platform in China, was launched in 2015. After 8 years of development, the company has grown into a one-stop supply chain service platform for 3D printing, CNC and other multi-technology. Wenext ranks at the forefront of the industry in terms of industrial scale, and has extensive industry influence and brand awareness in the field of 3D printing. Accumulatively serving more than 200,000 global innovative hardware enterprises, producing more than 30 million parts and more than 15 million models each year.

Subsequently, the visitors came to the metal additive manufacturing workshop of Wenext. Several HBD G350 metal additive manufacturing equipment are performing printing work. The laser sparkles and faster printing efficiency have won everyone's praise. HBD G350 is a high efficiency and high quality printing equipment, with more mainstream molding size, compatible single/dual laser configuration, efficient and stable powder dispensing system, closed automatic powder circulation system, independent long-term multi-stage purification system, t

- Categories: Events

- Author:

- Origin:

- Time of issue: 2023-03-11

- Views: 0

▲HBD Technology Development and Product Application Director Niu Liuhui Speech

Niu Liuhui, director of process development and product application of HBD, made a keynote speech on "Innovation and application trend sharing of metal Additive Manufacturing mold industry value chain". Director Niu said that the mold has entered the era of mass production in the application of metal additive manufacturing, and the improvement of application technology has brought about the reduction of 3D printing costs. The printing and forming of 200-300 kg of random waterway mold parts has been generally realized.

Award Ceremony

▲Award Ceremony

After the summit, the 11th member Congress of Guangdong Machinery and Mould Science and Technology Promotion Association exchange dinner and high quality enterprise award ceremony were held. Guangdong Machinery and Mould Technology Promotion Association would like to thank HBD for its support and dedication to the 8th International Advanced Manufacturing (Guangdong, China) Summit, and award a plaque.

Guangdong Machinery and Mould Science and Technology Promotion Association awarded Mr. Niu Liuhui the honorary title of "2023 AMIS International Advanced Manufacturing (Guangdong, China) Summit Speech Contribution".

▲HBD Chairman Liu Jianye Made a Speech

Liu Jianye, chairman of HBD, delivered a speech as a representative of high-quality enterprises. Liu said that he was very grateful to the Guangdong Model Association for this platform, which brings us very pragmatic services, leads you to learn the industry benchmarking, visits and learns the business management model of the example, and conducts business docking. HBD has long focused on metal 3D printing equipment, while providing related self-developed software and high-strength materials, such as AMES additive manufacturing intelligent system for full printing process management, high wear resistance mold steel above 60 degrees HRC60, large-scale additive workshop and process planning scheme. We are more willing to come to the customer site, fully open technical exchanges, with good equipment and good service to implemente the customer's cost and profit.

Visit Shenzhen WeNext Technology Co., Ltd.

On the morning of March 10th, Guangdong Machinery Mold Technology Promotion Association, Qingdao Mold Industry Association and many well-known outstanding entrepreneurs came to HBD strategic partner - Shenzhen WeNext Technology Co., Ltd. Zhang Shuhao, General manager of the Additive Business Division, and Li Shuoyang, senior director of the metal Additive Manufacturing Business Division introduced the current situation of the company's innovation and development.

WeNext Technology Co., Ltd (WeNext), the first and largest 3D printing service platform in China, was launched in 2015. After 8 years of development, the company has grown into a one-stop supply chain service platform for 3D printing, CNC and other multi-technology. Wenext ranks at the forefront of the industry in terms of industrial scale, and has extensive industry influence and brand awareness in the field of 3D printing. Accumulatively serving more than 200,000 global innovative hardware enterprises, producing more than 30 million parts and more than 15 million models each year.

Subsequently, the visitors came to the metal additive manufacturing workshop of Wenext. Several HBD G350 metal additive manufacturing equipment are performing printing work. The laser sparkles and faster printing efficiency have won everyone's praise. HBD G350 is a high efficiency and high quality printing equipment, with more mainstream molding size, compatible single/dual laser configuration, efficient and stable powder dispensing system, closed automatic powder circulation system, independent long-term multi-stage purification system, to meet the high efficiency, high strength, high quality, sustainable production needs.

HBD hopes to work with the majority of entrepreneurs,

seize the opportunities of technological innovation and technological upgrading, achieve better development, and effectively promote the development and progress of the mold industry.

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback