A "super tool" for Orthopedic Surgeons, Metal 3D printed Orthopedic Parts and instruments

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2022-06-24

- Views: 942

A "super tool" for Orthopedic Surgeons, Metal 3D printed Orthopedic Parts and instruments

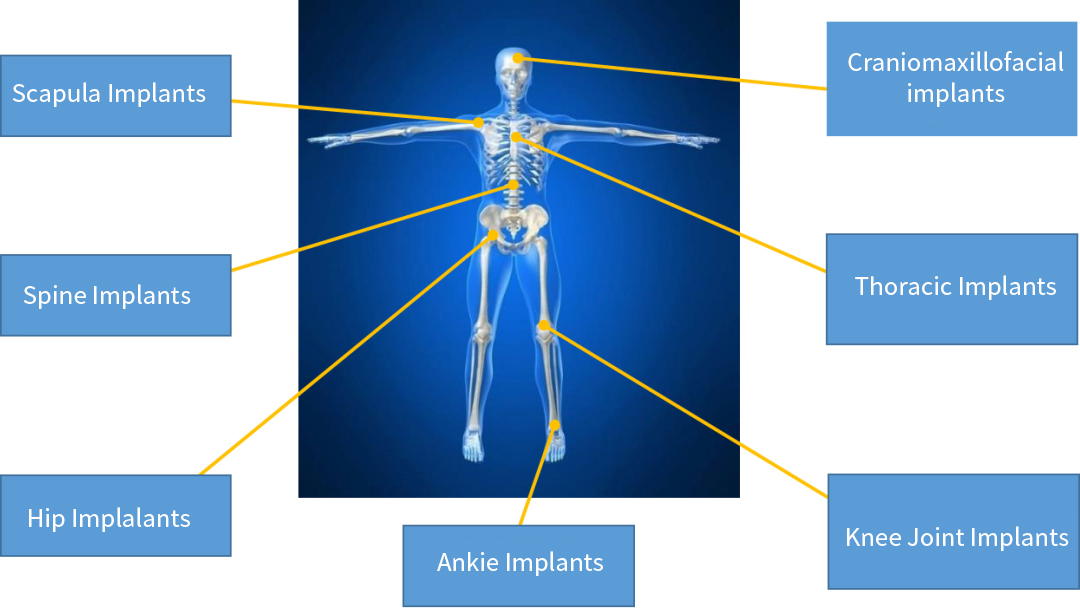

(Summary description)In recent years, there has been an increase in orthopedic treatment demand in China. In the aging population, spinal diseases, joint injuries, and orthopedic trauma are on the rise. Together with the improvement in people's consumption level and the promotion of national medical insurance, the willingness and frequency of orthopedic diseases to seek medical care have steadily increased, as well as the orthopedic medical device market.

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2022-06-24

- Views: 942

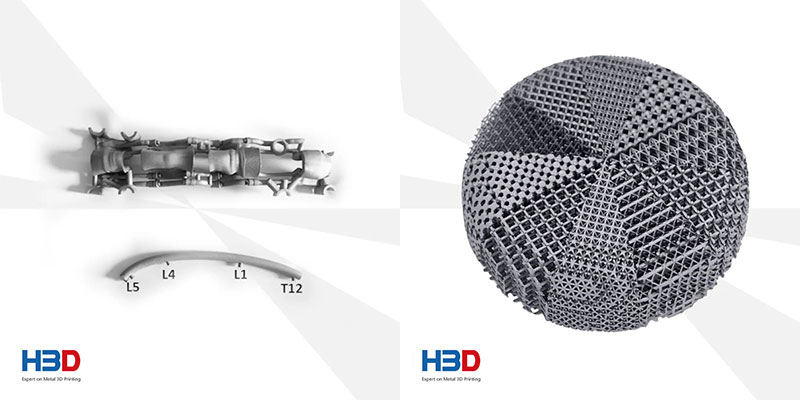

As technologies in upstream and downstream industries such as medicine, materials, and engineering continue to advance, orthopedic technology continues to progress in the direction of digitization, individualization, minimally invasiveness, precision, and intelligence. Typical innovative technologies include:

- Digital orthopedics, including the use of modern imaging technology, computer-aided measurement and design, rapid prototyping, etc.

- The rapid advancement of 3D printing technology has brought many possibilities for innovation in the field of orthopedic medical devices. As 3D printing technology has been used to personalize and customize surgical plans, accuracy and efficiency of surgery have improved, while risks have decreased.

- Also, tissue engineering, orthopedic regenerative medicine, orthopedic biomechanics, and nano-biomaterials have been applied to orthopedics to expand treatment possibilities.

A combination of precision medicine and intelligent medical technology will be the general trend in the future as the incidence of orthopedic diseases globally increases. In precision medicine, metal 3D printing technology is able to customize products according to the specific characteristics of patients' bones, allowing for rapid customization, reducing operation time, reducing risks, and improving the quality and efficiency of surgical operations. Meanwhile, the pain level of patients is also reduced and shortened, and the future will inevitably usher in a great period of development.

Huanwen Ding, Professor of National Engineering Research Center for Tissue Restoration and Reconstruction* Director of School of Medicine of SCUT, Chief Physician of Guangzhou First People's Hospital, has successfully customized multiple medical orthopedic devices with the ShoYii Intelligent Digital Precision Surgery Cloud Assisted System.

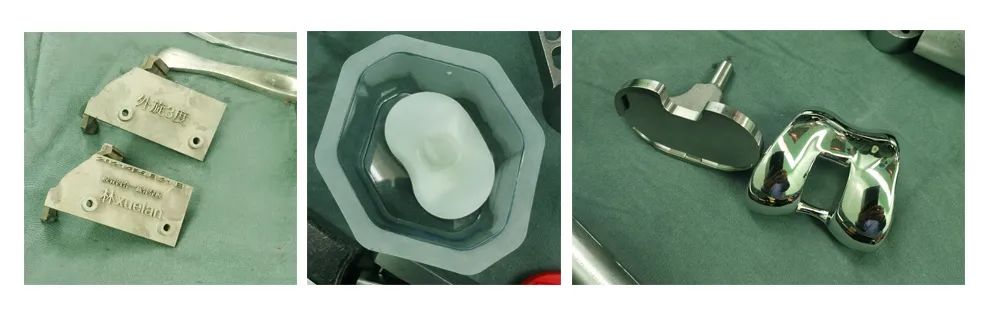

Case 1: Knee replacement surgery for osteoarthritis of the right knee

Case information

Summarize the case

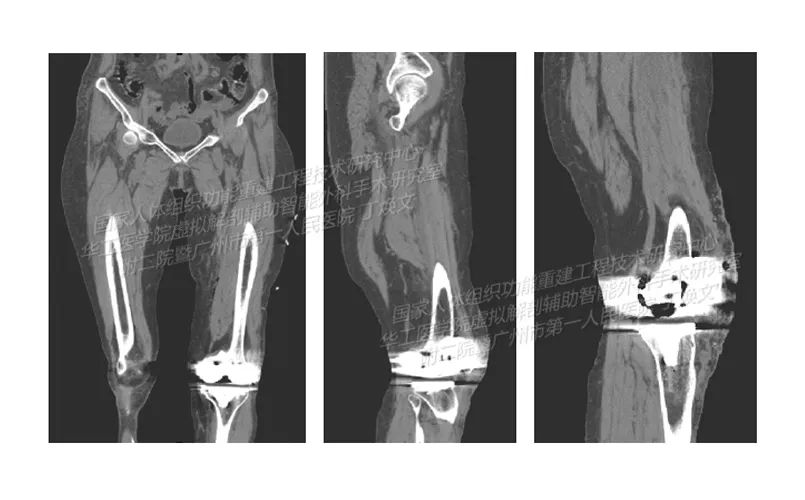

Medical history: 63-year-old female, Mrs. Lin. She has experienced knee pain for over six years. There is varus deformity of the knee joints, narrow medial joint space, dense subchondral bone margins, as well as bone hyperplasia around the joints.

3D Preoperative Reconstruction

Diagnosis

Knee osteoarthritis

The treatment plan

Precision knee replacement aided by digital and 3D printing technologies

The intraoperative situation

Using the knee joint model inversely modeled by CT and the metal 3D printing process, the digital medical team adjusted the forming direction of the surgical guide, optimized the support process, and selected the efficient and safe HBD-150 equipment for the quick preparation of the personalized knee joint surgical guide. A high degree of fit must be achieved between the surgical guide and the knee joint, the maximum deviation of the contour within 0.3mm, and the deviation of the positioning hole type within 0.1mm, to achieve high-precision positioning and navigation of bone screws, and to reduce the operation time by using the customized knee surgery guide. It can significantly reduce intraoperative blood loss and shorten the time required for postoperative recovery.

After-operative recovery

The patient recovered well from both knee injuries;

The CT scan showed that the left knee joint had been altered after replacement, that the individual knee joint was intact and that the structure was not broken.

Case 2: Sacral tumor resection and bone grafting in conjunction with lumbar spine surgeryn

Case information

Summarize the case

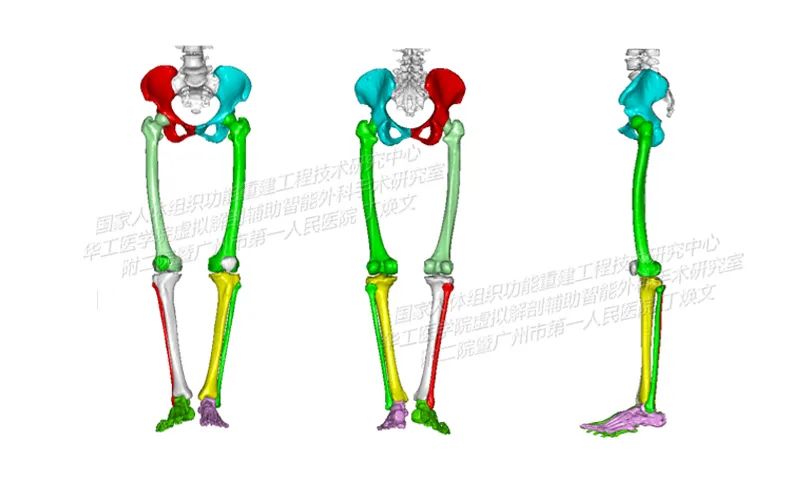

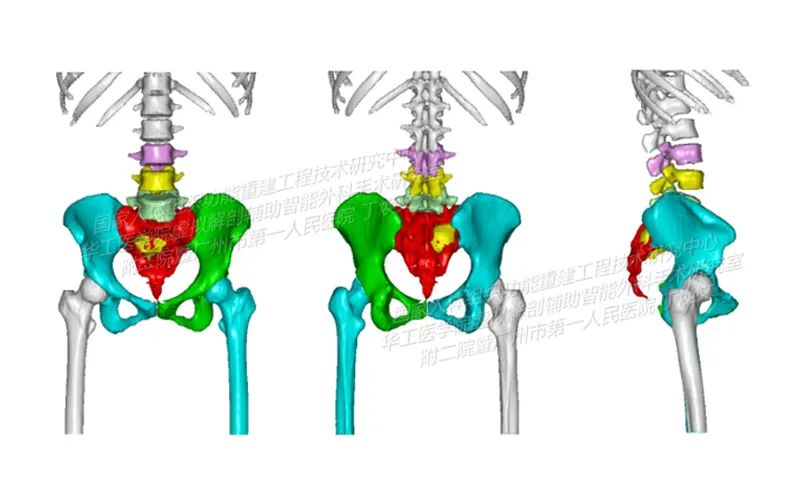

Mrs. Chen is a 44-year-old female. She developed low back pain three years ago, and right lower extremity edema with swelling and stiffness, which aggravated after physical activity one year ago. Her pain was treated symptomatically, but the symptoms did not disappear. Therefore, she was referred to the hospital for MRI. An MRI revealed a sacrococcygeal tumor.

3D preoperative reconstruction

Diagnosis

A giant cell tumor of the bone

The treatment plan

- Resection of the sacral tumor, bone grafting, and internal fixation of the lumbar pelvis;

- The intraoperative interventional department provides temporary right common iliac artery balloon occlusion and abdominal aortic balloon occlusion support.

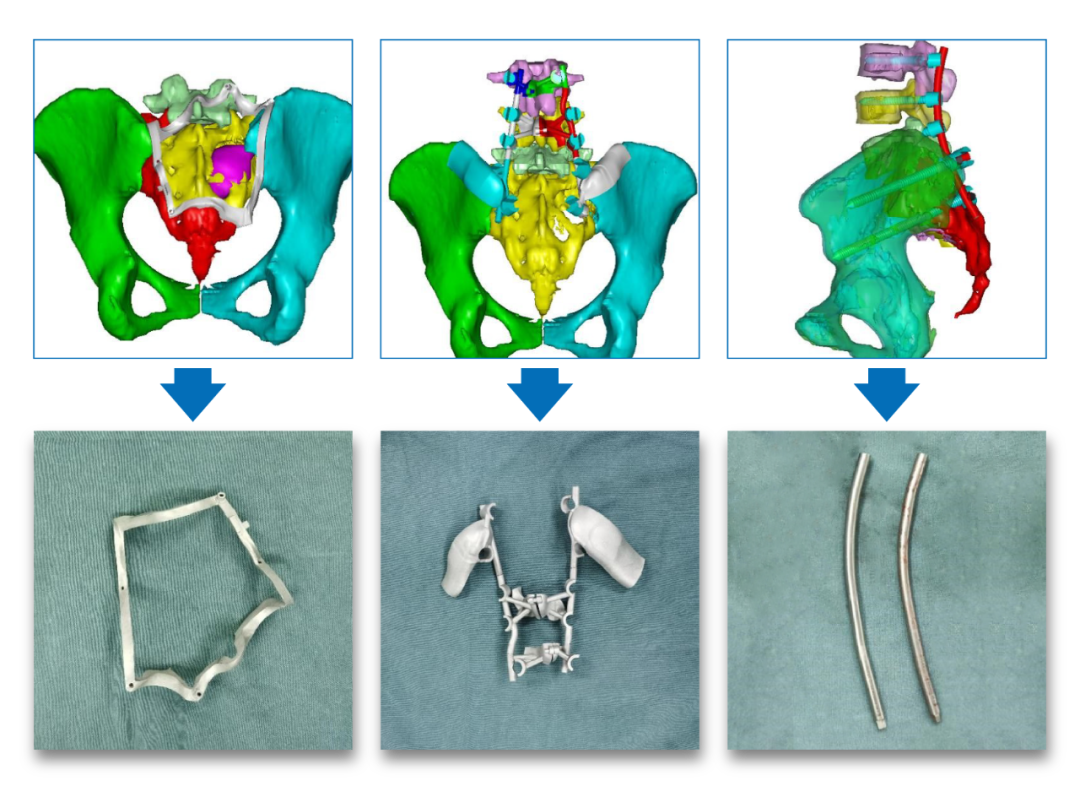

The intraoperative situation

As per the patient model and the needs of the attending physician, the digital medical team optimizes the printing model, adjusts the optimal molding angle, and strictly controls the support arrangement of the positioning guide and the bone contact surface. The digital medical team then accurately prints out each fine structure part using metal 3D printing technology. The HBD G350 is capable of preparing auxiliary drilling positioning guides, auxiliary osteotomy guides, and fixation rods very quickly. By adjusting the surgical guide plate, it can be tailored to match the patient's unique site, providing accurate positioning of the lesion during the operation, guiding the tumor resection in real time, enhancing the accuracy of the operation and effectively reducing its risk.

After-operative recovery

After correcting the sacrum and lumbar spine, the patient was in good health.

The X-ray revealed: the changes after radical sacral tumor removal + sacral reconstruction, the position of the prosthesis was appropriate, the spinal curve was normal, and there was no scoliosis. A proper match was made between the lumbar vertebrae, and the posterior edge was smoothed.

Metal 3D printing is characterized by precise processing, rapid production, and is not dependent upon special molds. Compared with standard-size orthopedic surgical guides, metal 3D printing tailored-made individual surgical guides are more accurate in the matching with the patient's bones and in the positioning of the surgical instruments. Orthopedic surgeons have gradually begun to recognize the concept and advantages of 3D printing technology.

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback