Conformal Cooling Channel Mold Case Study: Enhancing Product Qualification Rate in Medical Packaging Molds

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2024-03-04

- Views: 858

Conformal Cooling Channel Mold Case Study: Enhancing Product Qualification Rate in Medical Packaging Molds

(Summary description)In today's landscape, medical packaging companies' production lines are facing numerous challenges and dilemmas. With the constant evolution and innovation in the medical industry, the requirements for packaging materials have become increasingly stringent: ensuring product safety, hygiene, and efficacy. Simultaneously, there is a growing demand in the market for packaging processes and efficiency, pushing companies to seek more efficient production solutions while maintaining quality.

- Categories : Application & Client Stories

- Author:

- Origin:

- Issue Date : 2024-03-04

- Views: 858

In today's landscape, medical packaging companies' production lines are facing numerous challenges and dilemmas. With the constant evolution and innovation in the medical industry, the requirements for packaging materials have become increasingly stringent: ensuring product safety, hygiene, and efficacy. Simultaneously, there is a growing demand in the market for packaging processes and efficiency, pushing companies to seek more efficient production solutions while maintaining quality.

An established player in the medical industry dedicated to enhancing pharmaceutical packaging production quality and efficiency faced challenges with traditional water cooling molds used for bottle cap production. Issues such as product deformation and inconsistent sizing arose due to limitations in the core structure, leading to ineffective cooling of the cap rim and heat accumulation during continuous production. These hurdles impeded efforts to boost product qualification rates in a fiercely competitive industry.

Pharmaceutical Oral Solid PE Bottle

Recalling previous interactions with the HBD team regarding their Conformal Cooling Channel Mold 3D printing solution, the head of engineering promptly contacted our team to tackle the current challenge.

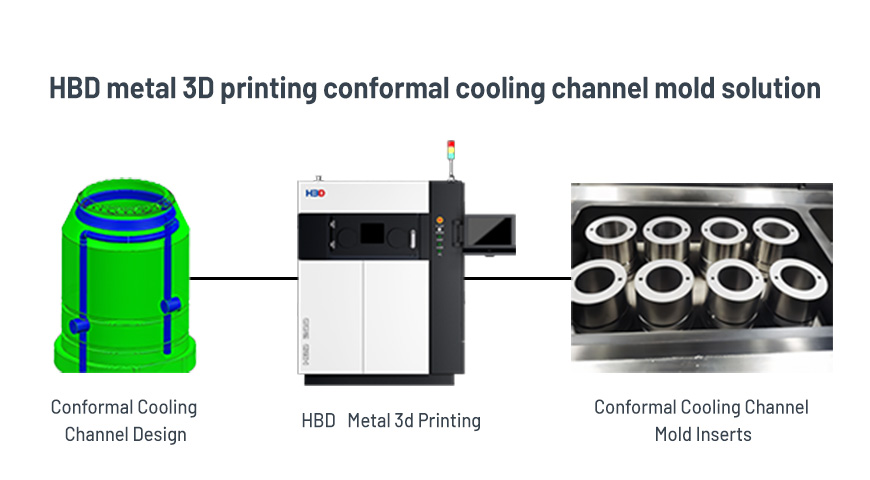

The HBD metal 3D printing conformal cooling channel mold solution proved instrumental in optimizing the mold by blending conformal cooling channel design with cutting-edge metal 3D printing technology.

Compared to conventional waterway molds, conformal cooling channel molds offer significant advantages by ensuring more effective and uniform mold cooling, thus reducing production cycles and enhancing efficiency.

Additionally, metal 3D printing technology enables flexibly design and manufacture intricate cooling channel geometries, facilitating optimal cooling medium contact with the mold surface to enhance cooling efficiency. This level of flexibility and precision surpasses traditional machining methods, providing manufacturers with increased design freedom and production efficiencies.

Following the integration of HBD conformal cooling channel mold inserts, significant improvements were observed at the company. Cooling time decreased from 12 to 10 seconds, and molding cycles shortened from 29 to 23 seconds, resulting in a remarkable increase in daily qualified output from 19,862 to 25,043 units compared to using traditional waterway molds.This optimization not only enhanced production efficiency and product quality but also boosted design flexibility and production advantages, reinstating thier confidence in facing industry competition.

Contact us now to find out how we can help you improve your productivity!

Scan the QR code to read on your phone

Contact with HBD

Crafting Tailored Metal AM Solutions Across Industries – HBD at Your Service.

新闻留言

联系信息

Your provided consents can be revoked at any point. To do so, you can reach out to HBD via email at info@hb3dp.com or through other specified means.

Shanghai Hanbang United 3D Tech Co., Ltd.

Address: Room 606, Tower C, Hongqiao Green Valley Plaza,

No. 518 Shen Chang Road, Minhang District, Shanghai, China

Guangdong Hanbang 3D Tech Co., Ltd.

Address: Hongji e Valley, No.23 Tongji Road West, Nantou, Zhongshan, Guangdong, China 528427

Follow Us

© Shanghai Hanbang United 3D Tech Co., Ltd. Privacy Policy Record number:粤ICP备20054270号

Headquarter:+86 21 3463 3208

Headquarter:+86 21 3463 3208

Feedback

Feedback